The Western Glass Manufacturing Company

By Mike Miller and Tom Katonak

Reprinted from "Crown Jewels of the Wire", July 2005, page 25

PART II: THE RISE and DEMISE OF WGM CO.

In Part I of this story, you read some of the history of the Western Flint

Glass Company and how in late 1900, the name of the company was changed to the

Western Glass Manufacturing Company. The new company started life with a

complete new set of insulator molds, four each for each of the five insulator

styles which were to be produced. In addition, they had brought in a new and

highly reputed plant manager from St. Louis, and he appeared to be "turning

the tide" for WGM.

Medium-dark purple WGM CD 121.

Thousands of these classic insulators were

used on

the phone lines throughout the Rocky Mountain West.

Rising Tides

The year 1901 appeared auspicious for WGM. "There are now 175 employees

and the factory is running night and day. Already upwards of $100,000 has been

expended and improvements and enlargements are constantly being made. Bottles,

insulators and milk jars are being made."¹

John Porter writes to his father on March 27, 1901: "Glass business

doing very well. I think, satisfied all the brewers with the quality of bottles,

and sold seven cars a few days since to Colorado Springs, but at a small profit,

this to get trade, keep outsiders away (and) also to keep market for our

product, think it all O.K."²

The year that began so promising did not end so well. According to the Rocky

Mountain News, "Michael Nester, manager of Western Glass Manufacturing is

confined to his home with a badly burned face and neck. The burns were caused by

a blowpipe in the hands of John Kerkendall, aged 14 years. Nester saw Kirkendall

smoking a pipe and ordered him to put it away. A little later, Nester saw

Kirkendall smoking the pipe again and discharged him. Nester turned to walk away

when Kerkendall picked up the blowpipe which he had partly cleaned and struck

Nester on the shoulder... The end of the pipe was red hot. Before Nester had

time to recover, Kirkendall struck him on the head, which staggered him, and as

he turned around, the boy jabbed the hot iron into his right cheek. Then he

struck him on the head again... there were four members of the Kerkendall family employed at the works but they have all been discharged on

account of the assault."³

On December 28, 1901, came the bane of all glass plants -- fire! "..

.it was first noticed by Night Foreman Wambacher shortly before 1 o'clock this

morning. At that time there was nothing to it but a slight blaze in the roof.

The men immediately quit work and ran for the hose and other fire apparatus, but

before they could get the hose turned on the fire had spread all over the roof

and to the small oil tanks which are near the roof... The men could not use

water too lavishly for fear of getting it into the great furnace of molten glass

which would have exploded if water had gotten into it... It is the intention to

clean out and refit the operating room without a roof as soon as the machinery

is in place. If the weather will permit, the employees will work while the

carpenters are putting on the roof."(4)

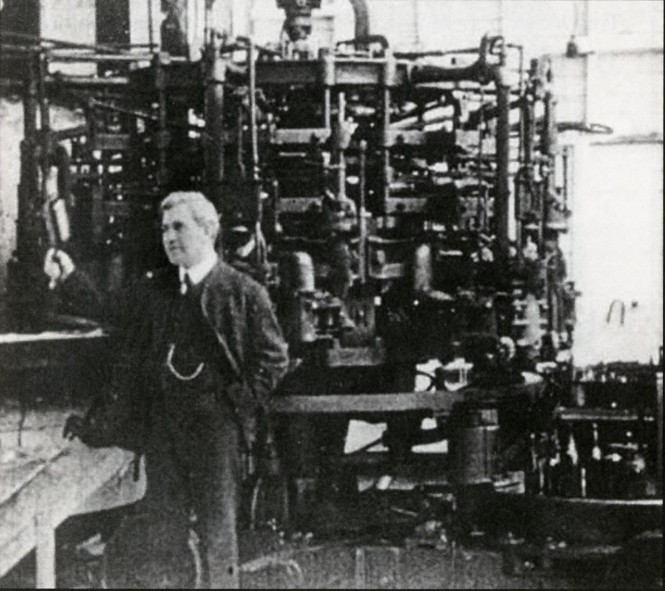

Inventor Michael Owens with his famous automatic

bottle making machine (photo

circa 1904)

This WGM beehive shows definite signs of touching up

against another hot

insulator in the cooling lehr.

This defect is called a "hairlip" and results from too small of a

"gather" being dropped

into the mold. As with other defects, this is

also uncommon in WGM products.

"The Whale"

Another example of a "polliwog" in the glass. Such artifacts are

quite uncommon.

It was necessary to always keep an eye on the competition. "Hitherto,

Pittsburgh

and Alton factories have monopolized the industry of glass manufacture, but

the chamber of commerce reports the Denver institution as being an excellent

competitor, which as promise of gaining markets in every part of the United

States, and of ultimately supplying Mexico and south America."(5)

"Large contracts have been made with C.A. Lammers, Adolph Coors, Neef

Bros., Beebe-Crauel Pickle co., Colorado Telephone co., Manitou Mineral Water

co., Anheuser-Busch and others. These firms appreciate the convenience and

desirability of having their ware made at home and are very loyal in their

support."(6)

On April 21, 1902 John Porter attempts to sell some whiskey flasks to Harry

Kelly of the Gross Kelly Co. (wholesale grocers) in Las Vegas New Mexico.

"We started this factory some three years ago; we have to depend on the

local and western market; we want and need your business; we try to give

satisfaction.. ."(7) Friendship and supporting local industries is fine, but

in the end it comes down to price. On April 25th Harry Kelly replies, "I assure you we would be

more than pleased to confine our flask trade to you if we possibly could. We

only buy these flasks to job them again and our margin is very close, and our

Mr. Earickson informs us that your price is somewhat out of line which was

quoted him. If you can get in line we would be more than pleased to give you the

business at even money."( 8)

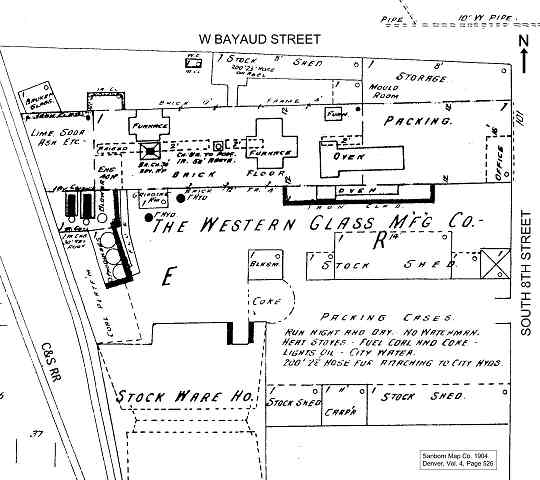

1904 Sanborn Map Showing the WGM Operation in it's "Heyday"

On January 8, 1903 WGM bought the glass plant and land (lots 1 to 13 and 38

to 48 of Block 17 Valverde) from Emma Tomson of Philadelphia.(9) Mrs. Tomson's

late husband had built the original glass plant in 1886.(10)

Michael Nester left WGM in the spring of 1903 to manage the glass plant in

Kansas city which had recently been purchased by the family's firm Obear-Nester

of East St. Louis. "The employees (of WGM) assembled in the packing room

recently and A. J. Henderson, in a neat and appropriate speech, presented Mr.

Nester with a diamond stud as a token of the esteem in which he is held by those

who have been associated with him during the past three years."(11) Later

"the glass workers gave Mr. Nester a farewell surprise at his home.

Refreshments were served by the ladies and music, songs and dancing were

enjoyed."(12)

The Decline Begins

May 5, 1906 - the front page headlines said it all: "WESTERN GLASS

COMPANY'S PLANT IS TOTALLY DESTROYED BY FIRE - Loss $150,000 and 200 people are

thrown out of employment"(13) "Fanned by a fierce wind, a fire which

broke out in the gas producing plant. ..of the Western Glass Manufacturing

Company yesterday afternoon developed into a veritable holocaust and destroyed

the entire property."(14) "M. W. Gano, general manager of the company...

early got to the scene of the fire. He was downtown when he first heard of it

and made a record-breaking trip of four miles in his automobile."(15)

Mr. Gano told the Times reporter "We were overcrowded with orders,

enough to keep us busy for a year at least. We had just entered on our period of

greatest prosperity. We were counting on making additions. We are confident

enough of the future to rebuild on a larger scale and in a more substantial

manner."(16) The plant destroyed was that shown on the 1904 Sanborn map.

Merritt Gano's confidence was misplaced. Forces were at work that would lead to

the triumph of the Pittsburgh and Alton glass companies. This revolution was

coming out of Toledo, Ohio, from the brain of Michael J. Owens. Frank M. Gessner

describes the Owens bottle machine: "... it gathers its glass, forms its

blanks, transfers the blank from the gathering mold to a blow mold with a

finished lip and ring, blows the bottle and delivers the finished bottle

automatically without the touch of the human hand, eliminates all skill and

labor and puts the same amount of glass into every bottle, makes every bottle of

the same length, finish, weight and capacity, it wastes no glass, uses no pipes,

snaps, finishing tools, glory holes, rosin, charcoal, and requires neither gatherer, mold boy,

snap boy nor finisher and still makes better bottles, more of them than by any

other process." ( 17)

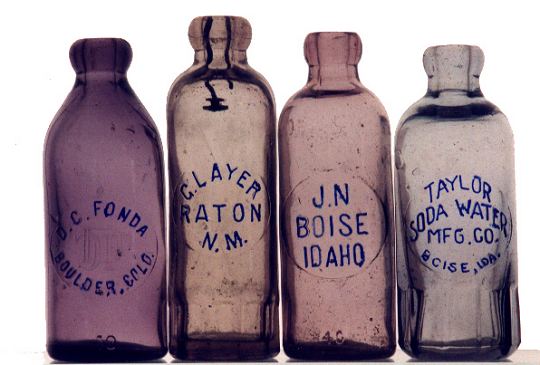

WGM Peach Colored Toll

WGM Hutch Bottles

Showing Regional Distribution. Bottles were the main

product of the WGM glass plant and were sold to companies all over the west.

Various Color Variants and Mold Styles for the CD 134 Style Relatively few

134s were produced: Current research suggests WGM Co. resurrected the older WFG

134 style molds to fill customer orders. Note how the second piece from the

right is slumped: Such a defect is unusual for WGM production.

WGM CD 162 "signal" insulators

showing various colors and mold

styles

The gathering chill may be felt in John Porter's letter to Gerald Hughes of

March 23, 1907: "Merritt called me up and said that last month we made some

$19,000 of glass, with a net profit of $1,700... nothing particular new in this

direction."(18) Gone is the sense of optimism evident in the summer of 1900

when they expected the works to produce a profit of $200 per day on a much

smaller investment.

A time-honored response to financial problems is to cut expenses, including

wages. The Denver Post reports on a 'come to Jesus' meeting in Valverde between

the management of WGM and an officer of the Glass Blowers Union. "When the

works closed down last season it became generally known that an effort would be

made to reorganize the working force with non-union men. The matters in dispute

have been amicably settled... The wage scale remains the same as

heretofore."(19)

Local 30 (Denver) of the Glass Bottles Blowers joined the Colorado State

Federation of Labor in April 1906 and contributed 2¢ per member per month to the

State Federation. According to the Federation's ledger, Local 30 had 35 members

from April 1906 through June 1907. They had dropped to 30 members September 1907

through June 1908, and had dropped further to 23 members September 1908 to the

closing of the plant in May 1909. These were skilled blowers, not helpers or

apprentices.(20)

Nine months after closing, there was still a little matter of indebtedness to

the Denver National Bank. John Porter writes plaintively to his father on

February 15, 1910, "I drew from your account today to pay my share of an

assessment for the Glass Co. of $10,000; $1,568. This cuts the bank down to

$15,000 which I think they will carry now for a time, and we want to do

something with what is out there for it is not improving with time and

exposure."(21)

So, it was the Owens' bottle machine that ended the life of the Western Glass

Manufacturing Company... and all the small plants across the country that blew

bottles with a blowpipe and finished them by hand. As George H. Foster of Robert

Good Sr.'s plant said, "When automatic machines were invented, that settled

their hash."(22) As elegy for all these little glass plants, a quote from a

veteran year blower Charles Miller at the Poughkeepsie, NY plant of Robert Good

Sr. seems appropriate: "Glass blowing was an elegant trade. I don't think

there's any hand blowing now. Even little glass pill bottles are made by

machine. Machines killed everything. Eventually the whole thing here, tools,

molds and everything was sold as junk. All was taken away on a barge."(23)

Color comparison between WGM and AMTEL CD 121s.

Evidence now suggests that

WGM Co. made the

unembossed AMTELs late in their production history.

Notes:

1. Denver Times, February 28,1901

2. Porter Papers; Colorado Historical

Society

3. Rocky Mountain News, December 7, 1901

4. Denver Times, December

28, 1901

5. Denver Times, May 25, 1902

6. Denver Times, December 28, 1901

7.

Porter Papers, loc. Cit.

8. Ibid.

9. Denver Post, January 11, 1903

10. Rocky Mountain News, November 21, 1886

11. Commoner & GlassWorker, V24,

#28, April 18, 1903

12. Ibid.

13. Denver Republican, May 5, 1906

14. Ibid.

15. Denver Times, May 5, 1906

16. Ibid.

17. Walbridge, William S., American bottles Old & New, Toledo, OH,

1920

18. Porter Papers, loc. Cit.

19. Deliver Post, October 5, 1908

20. Western

History collection, Norlin Library, CU, Boulder, CO

21. Porter Papers, loc. Cit.

22. Poughkeepsie Sunday New Yorker, February 7, 1948

23. Poughkeepsie Sunday New Yorker, March 1, 1953; Charles Miller as quoted by Helen Myers

24. Toledo Blade,

February 22, 2005

|